Neudert - 4-sided sealed-edge flat bag machine - we bagged it up

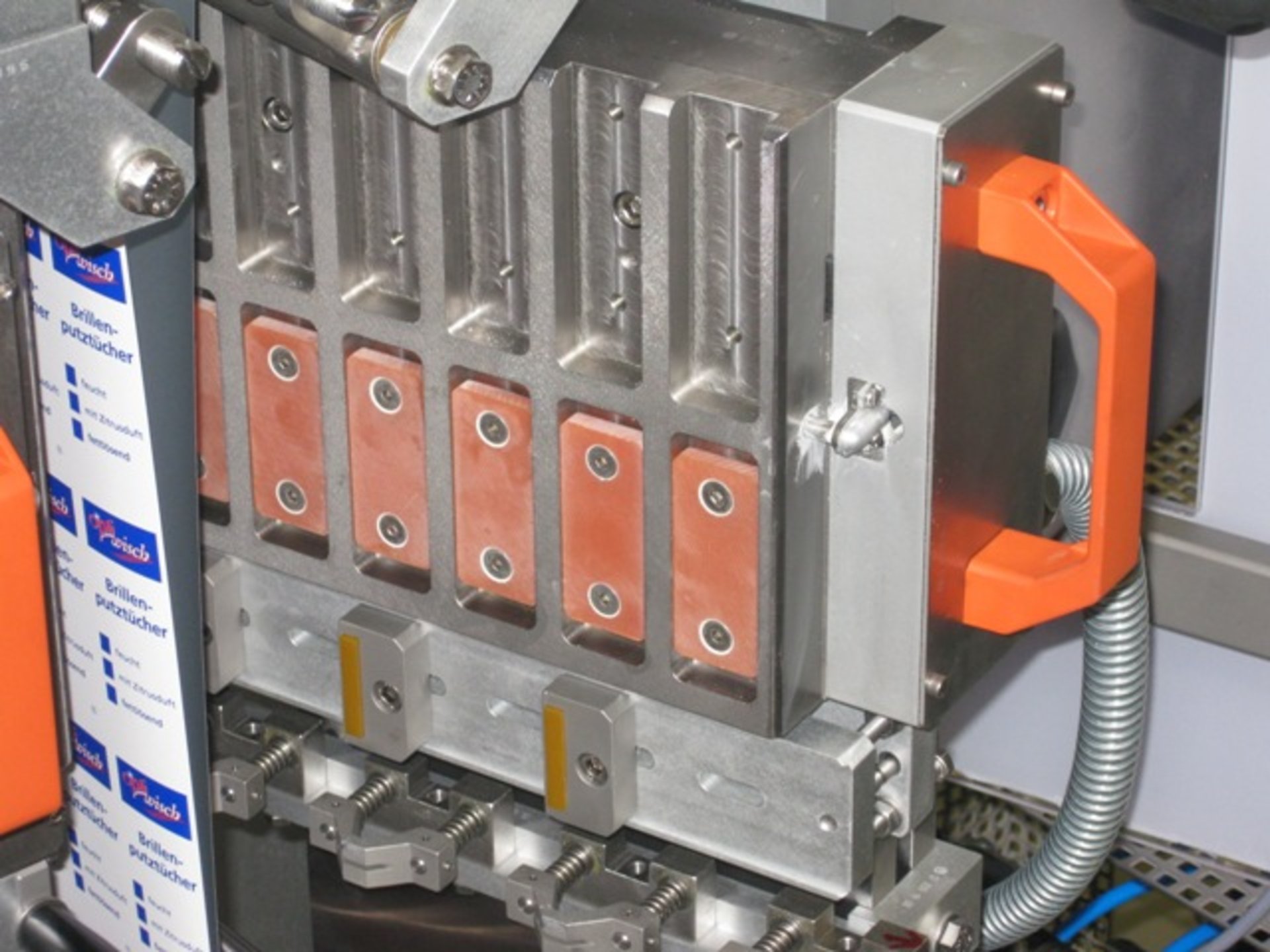

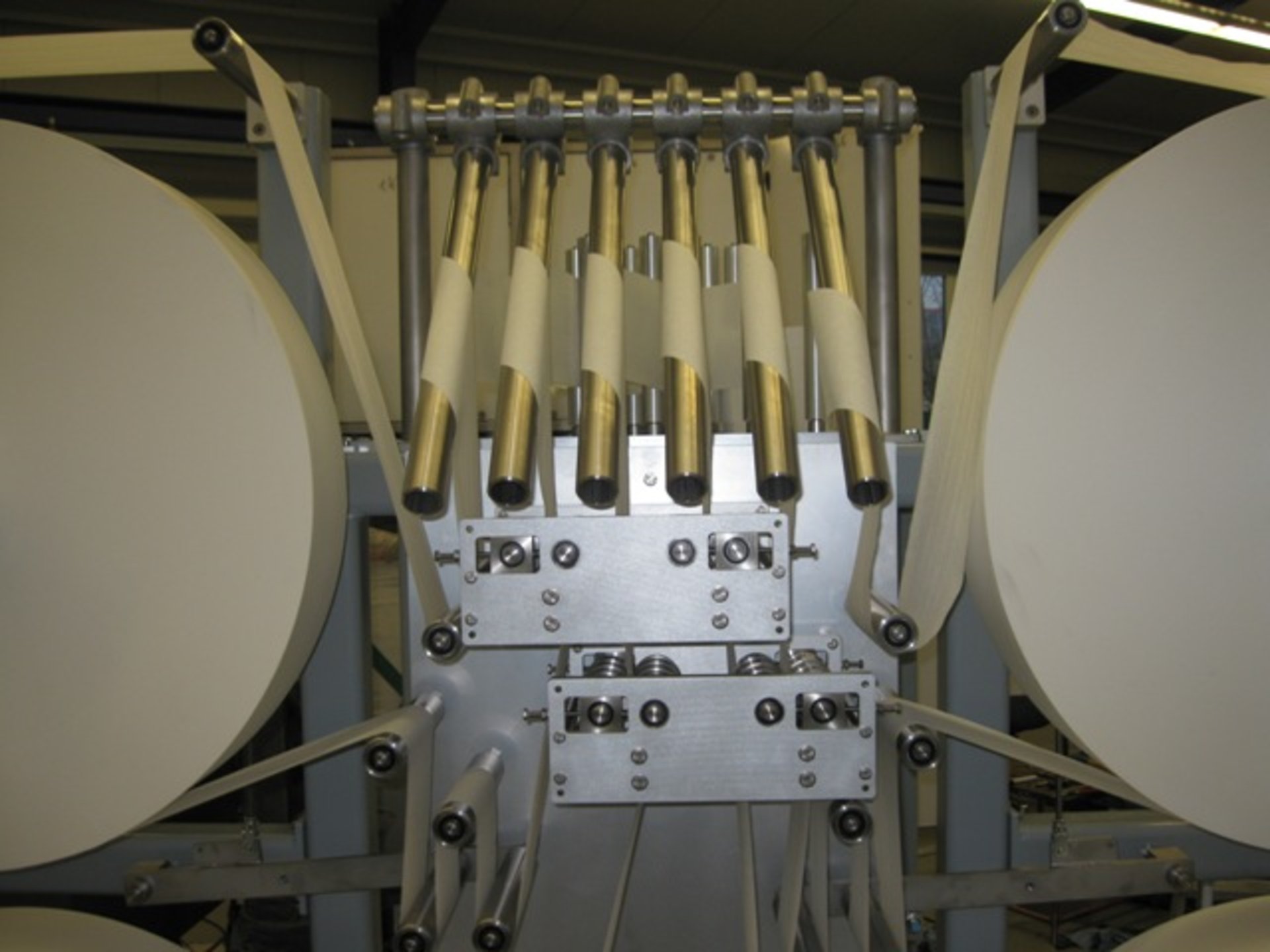

Glasses cleaning wipes, refreshment wipes, swabs in medicine, all applications when hygienically packaged wet wipes are used. Entire companies have specialized in the manufacture and packaging of these towels. Large rolls of fabric are used to unroll, cut and fold the cloth. The packaging, a flat pouch made of foil, is made, the cloth is placed in the pouch, the desired liquid is added and the pouch is then sealed.

There are a wide variety of machines on the market to carry out these steps. Every machine manufacturer approaches the matter with different ideas and ideas. But the real know-how lies with the users, i.e. the producers of such wipes.

It was precisely these considerations that prompted one of our customers, a packaging company specializing in the manufacture and distribution of such towels, to develop their own machine. Together with an engineering office, a complete machine was designed here, taking into account the needs of this company, tailor-made for these special requirements.

But what use is the best construction if nobody can implement it in reality. And that's where Neudert came in. As a system supplier, the entire machine was mechanically manufactured at Neudert, all parts were manufactured at Neudert, the purchase and standard parts procurement was organized by Neudert, and the complete machine was assembled in-house until a trial run.

Only the electrical and electronics were provided at the customer's request, installed by our customer in our assembly, so that a functional machine has left our house.

Modernized if your own idea should also become a reality.